OUR FAMILIES OF PRODUCTS

Discover the systems developed for you, according to your needs and evolving over time!

Cobotics

YOUR ROBOTICS / COBOTICS / AUTOMATION PARTNER!

We speak your language: Your process is our expertise.

Based on our customer experience in the field of manufacturing and integration of electronic cards, STPConcept has structured its offer in automation.

The development of complete applications or technological bricks are deployed and adapted for your production environments.

Our technical and economic approach has been worked on to offer innovative solutions dedicated to the manufacture of small and medium series.

This offer has been built and above all expanded very quickly in close collaboration with the field and a strong increase in the skills of our employees.

We work to anticipate your needs, by conducting an important technological watch on the choice and recommendations of equipment and by integrating a logic of “standardisation” of applications.

For example

- Robot / Cobot Vision

- Robot / Cobot Screwing

- Robot / Cobot Tester

- Our mobile chassis and indexing systems

And going even further with :

- Our own specific conveyors for electronic cards

- An integrated linear motor XY table system

- Our patented universal PCB holding tray

- Our vision scanners

All these technological building blocks can be integrated, modulated differently according to each application.

This continuous research, these developments that we have carried out, build today much more than yesterday, our capacity of adaptation and our flexibility.

The flexibility and agility that French industry needs is a concrete thought at STPConcept.

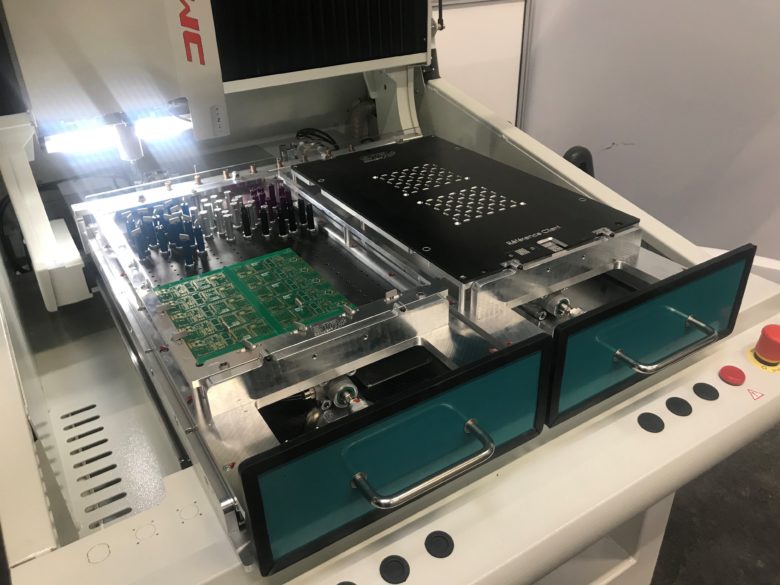

Depaneling

Router Depaneling : A tool cuts the attachments points by milling without stress for the components.

The routing is the most appropriate industrial technology for separating PCBs attachments points at the end of the production.

Indeed, thanks to this process: components welding points close to the technical edge don’t suffer any stress that can damage them and generate quality problems over time.

Concerning quality level, the integrated suction system integrated around the tool and controlled by the Machin leaves no residue.

Increase productivity with automated depaneling!

Inspection

Inspection of complex electronic boards!

The complexity and density of today’s hardwired boards makes the use of inspection machines more and more essential …

Daily, on automatic assembly lines, operator inspect the quality of manufacture. But is it really a job for them?

Indeed, the rhythm of assembly lines have become too fast. The eyes are no longer sufficient for ultra-fine manufacturing processes on which we are now.

Fortunately, solutions exist!

STPConcept offers its solutions in ISP and AOI.

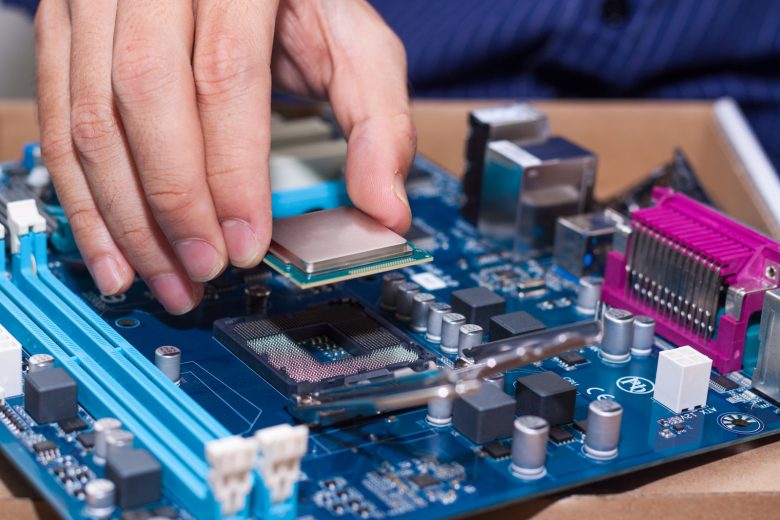

Repair

Why repair BGAs on site?

On-site BGA repair is now essential.

Despite quality assurance, or control measures, production defects are inevitable. Even the most modern production line can lead to mistakes.

It is becoming increasingly important to be able to replace enclosures of any type on boards assembled with maximum security, and with the lowest possible cost.

We can help you !

Storage

A unique solution for stocking and to identify stencils!

You wish:

- Save time at the beginning of the manufacture

- Follow your stencils evolution

- Delete the cardboard packaging residues

- Store all your stencils at the same place

E-STORAGE is THE solution