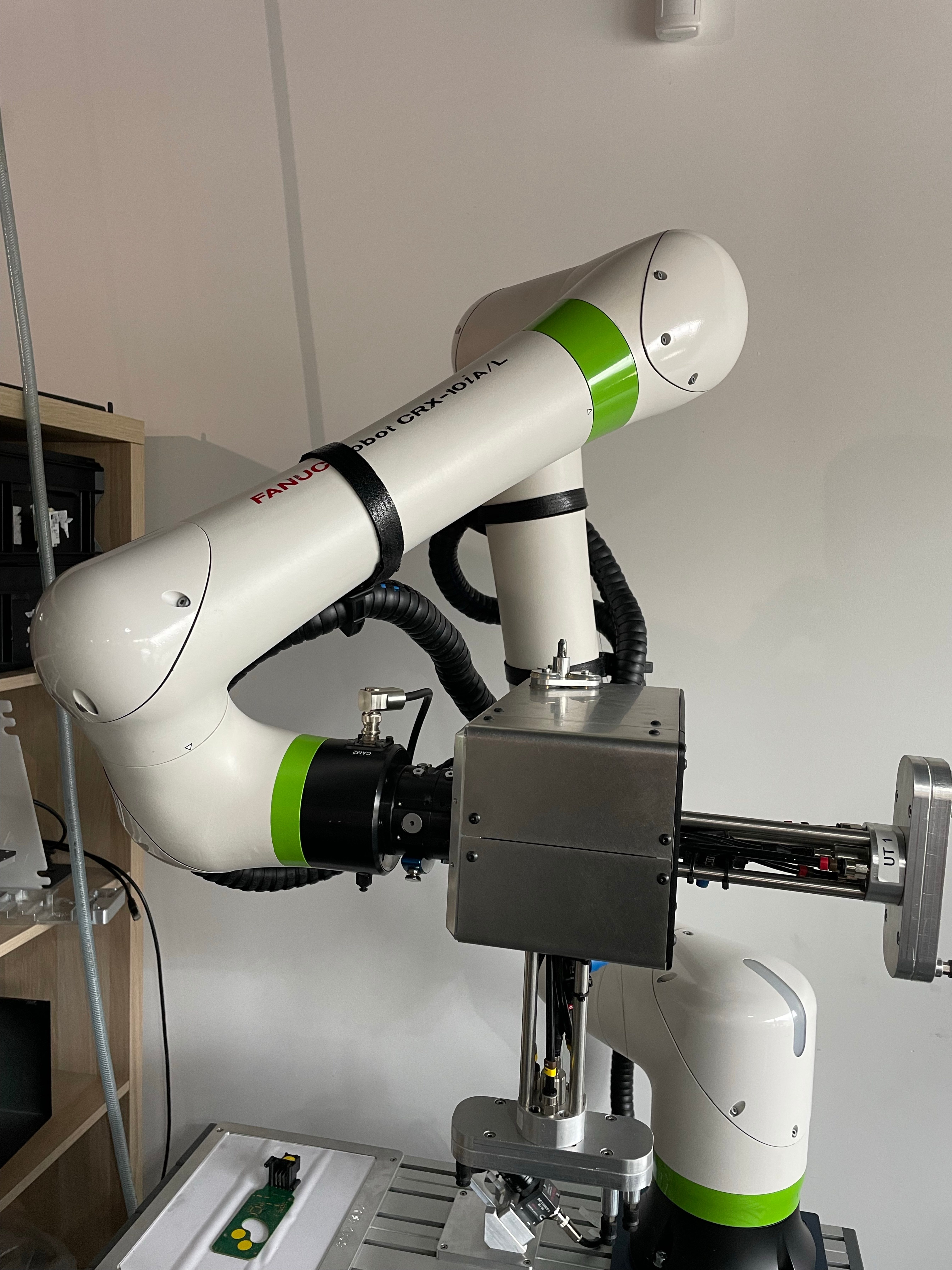

TESTING ROBOT

The objective of this solution is to automate the testing of electronic boards in small and medium-sized series and to integrate a robot in the most compact environment possible.

The cell will be flexible and will allow the customer to program his new products to be tested.

It has also been designed to integrate into the customer’s existing environment and index with existing testers.

The device automatically unloads products from their upstream conveyor, detects the parts, opens the tester, retrieves the tested part, repositioning it directly into its intended packaging for shipment.

This innovation is part of the industry of the future!

See productsFunctions details

Summary of the synoptic

- Detecting and taking the cards before the test

- Opening and closing the test

- Dialogue with the tester to recover the test result

- Recovery of the tested card

- If OK, it will be put directly into a blister pack and the blister pack will be put into a cardboard box to prepare for shipping

These operations take place in a single cycle without human intervention.

A specific and packaged gripper head allows the station to perform all these operations with a single tool.

Bonus

FACILITATE TEST OPERATORS WITH A “FLEXIBLE” CELL

SIMPLIFIED PROGRAMMING TO PROGRAM DIFFERENT TYPES OF PRODUCTS, REFERENCES, ETC.

THE AUTOMATION OF THIS STATION ALLOWS OPERATORS TO BE RELIEVED OF THESE REPETITIVE TASKS

A SOLUTION ADAPTED TO SMALL AND MEDIUM SERIES