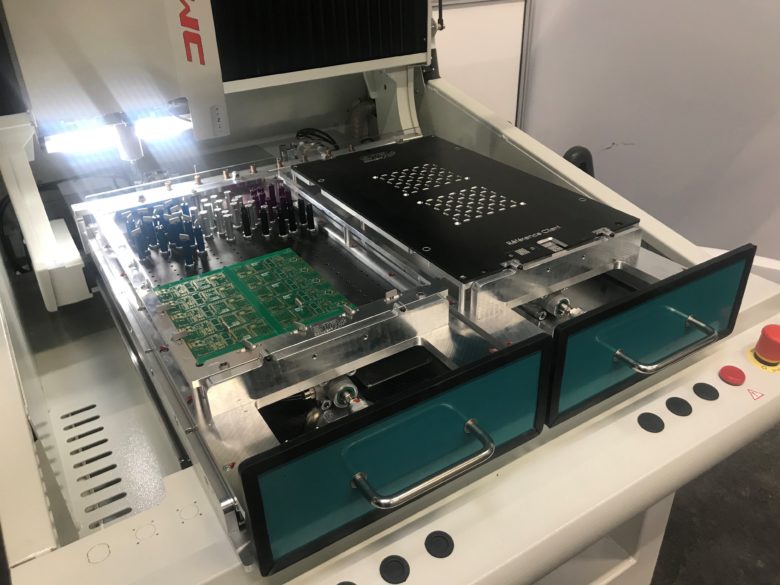

AOI Inspection

AOI Inspection : improve the quality of your electronic boards

Inspection of complex electronic boards!

The complexity and density of wired boards make automated inspection essential. On assembly lines, human inspection is no longer sufficient in the face of ultra-fine manufacturing processes and high production rates.

Our solutions:

FAI (First Article Inspection): complete verification of the first boards produced.

AOI (Automated Optical Inspection): automated inspection to detect defects and anomalies on your boards.

With STPConcept, ensure the quality, reliability, and performance of your electronic boards thanks to inspection solutions tailored to your production lines.