COBOT VISION

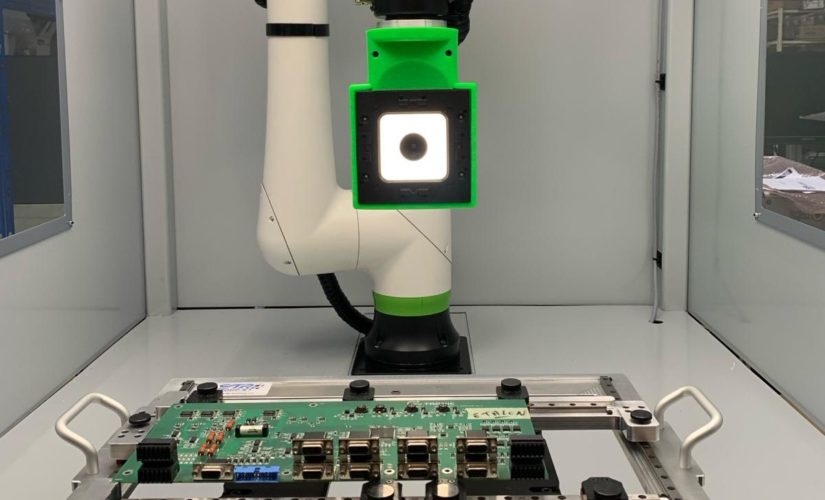

This cobotic solution (CV400) aims to assist visual inspection thanks to its expert system working in collaboration with operators.

This collaborative robot focuses on atypical end-of-line inspections such as labels, wire modifications, fasteners, gluing, absence of scratches, foreign bodies, varnishes, etc., depending on your needs.

The cell will be interoperable with its ecosystem and will enable the collection and sharing of information that can be used for diagnosis, as well as for addressing causes at upstream stations.

The industrial robot includes a cell that allows for universal or customizable loading, which can be designed according to your various projects and specific specifications.

This innovation is part of the Industry 4.0 era, responding to the many demands in the automatic inspection sector!

See productsFunctions details

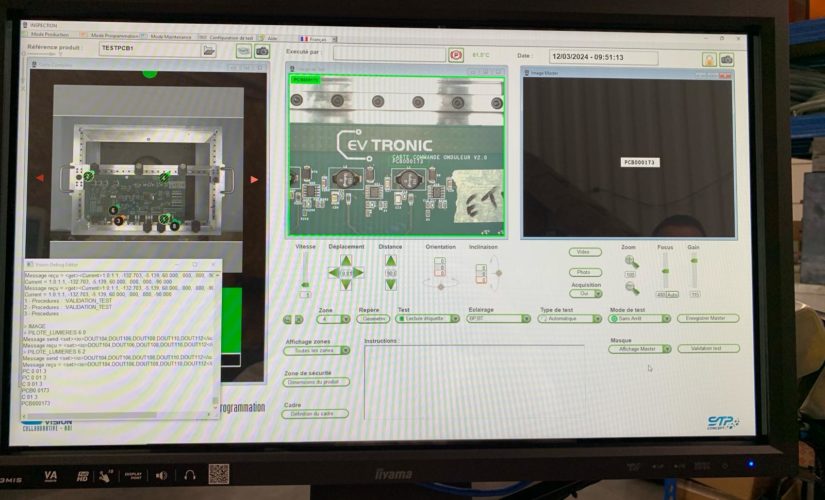

- Code and Data Matrix reading

- OCR and OCV function

- Advanced functions dedicated to wire rework, with optimized cable path analysis

- Intruder analysis on a board

- Color detection, filling, counting enabling the analysis of:

- SMD or through-hole components

- Polarity and direction

- Presence and filling of glue or resin

- Pin counting in connectors

- Standard or specific test patternThey talk about us:

Lacroix : https://www.lacroix-electronics.fr/smart-stories/smart-industry-fr/secret-de-fabrique-le-tout-nouveau-cobot-dinspection-optique-automatisee-aoi-de-lacroix-electronics/

Bosch : https://www.bosch-mondeville.fr/blog-et-presse/le-robot-collaboratif-apas-au-service-de-la-qualite/

Bonus

- Assist inspection operators with an “open cell”

- Simplified programming for different types of products and references

- With its 6 axes, the robot offers every possible viewing angle!

- Ideal for inspecting large-volume boxes and sub-assemblies

- A solution suited to small and medium production runs