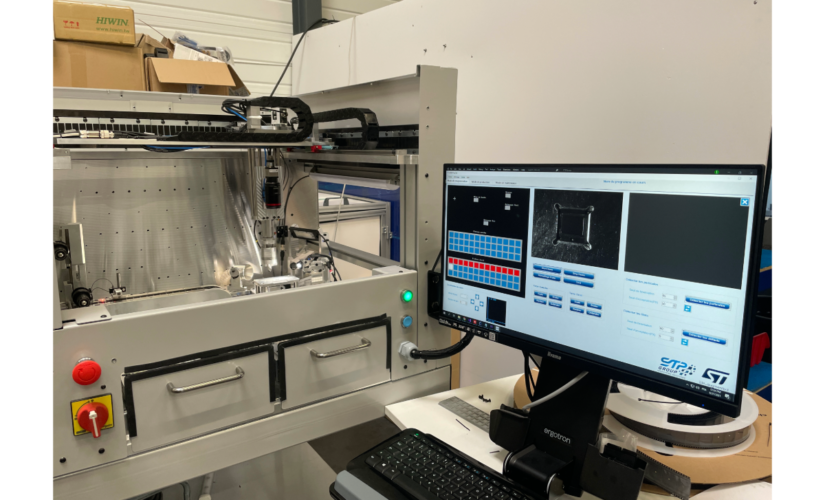

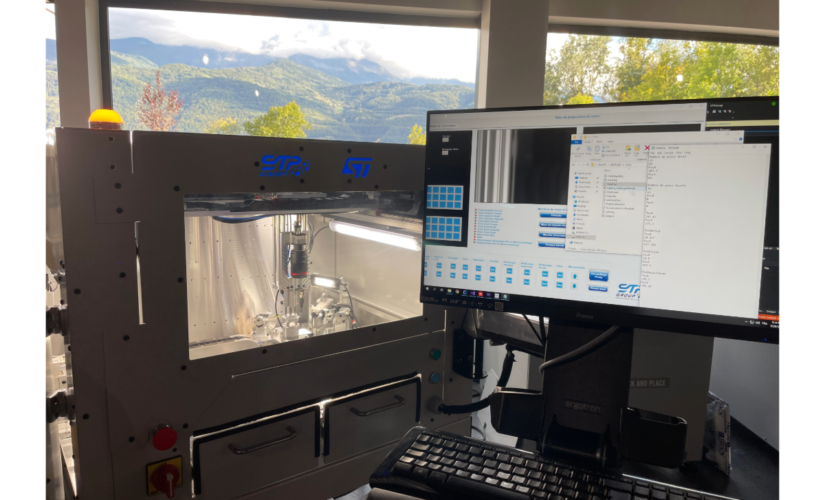

Banding machine

Development of a semi-automatic striping machine

We design and develop a semi-automatic striping machine suitable for restricted environments, particularly Class 10,000 clean rooms (to be confirmed according to your requirements).

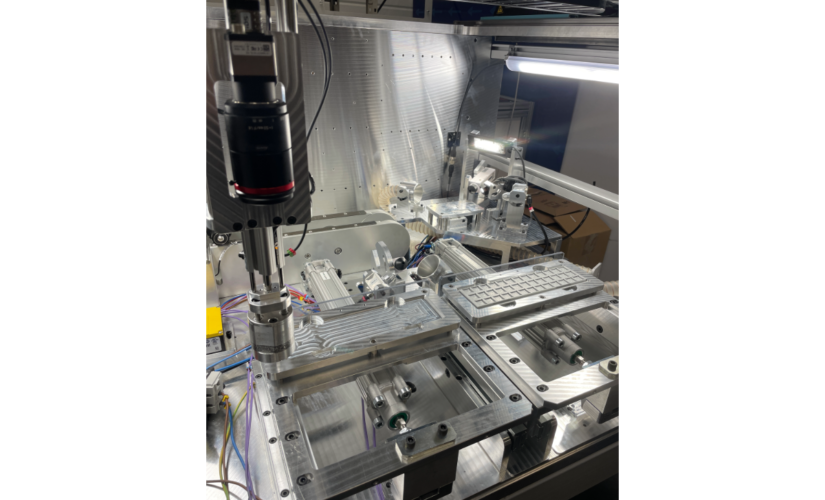

Automated handling process:

- Component picked up from the tray.

- Automatic cleaning of the underside and then the top of the component.

- Compliance check via sensors and integrated vision.

- If the component is compliant (OK): automatic deposit in the striping module.

- If the component is non-compliant (NOK): return to its original position on the tray.

Functions details

Main technical characteristics:

- Type of parts processed: 12 x 12 mm glass panels, taken from a tray and integrated into a honeycomb strip.

- Integrated cleaning cycle: removal of particles from each component, ensuring treatment that complies with microelectronics and optics requirements.

- Specific quality control: detection of a thin glue path and particles ≥ 10 microns in size.

- Tray loading: manual feeding via a double drawer system allowing for simultaneous operations and optimized productivity.

Bonus

- Optimization of precision and reliability in clean rooms.

- Reduced risk of particle contamination.

- Increased productivity thanks to dual drawers and partial automation.

- Adaptability to the specific needs of the microelectronics, optics, and medical sectors.